Lightweight,Durable,Sustainable

Your Global Sustainable Material Partner.Serving 500+ wholesalers worldwide since 2015.Annual production capacity: 1 million square meters of composite panels, customer repurchase rate: 82%.We don't sell slabs – we sell freedom from weight constraints."—— Dr. Chen, PhD in Polymer Science

Trending now

-

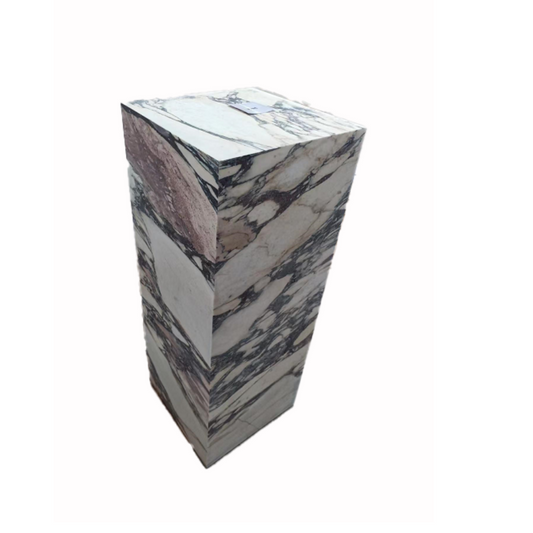

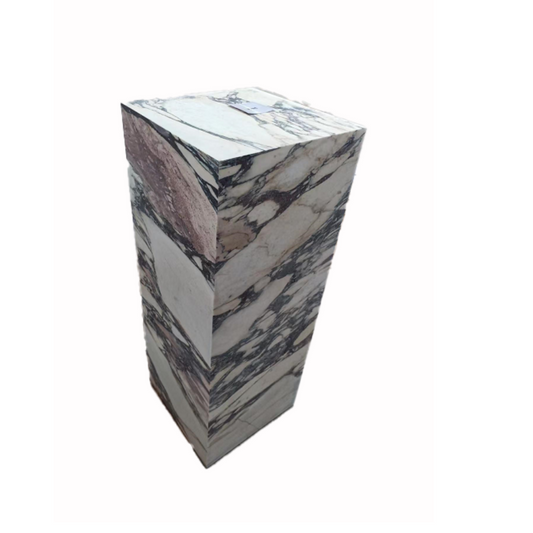

Combining the luxury of natural marble with high-molecular composite materials, it features high-end design and low maintenance. Natural aesthetics + Functionality

Explore -

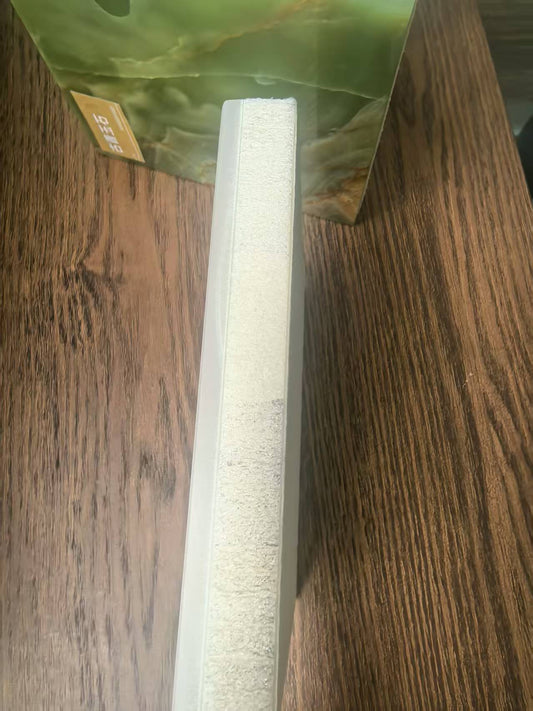

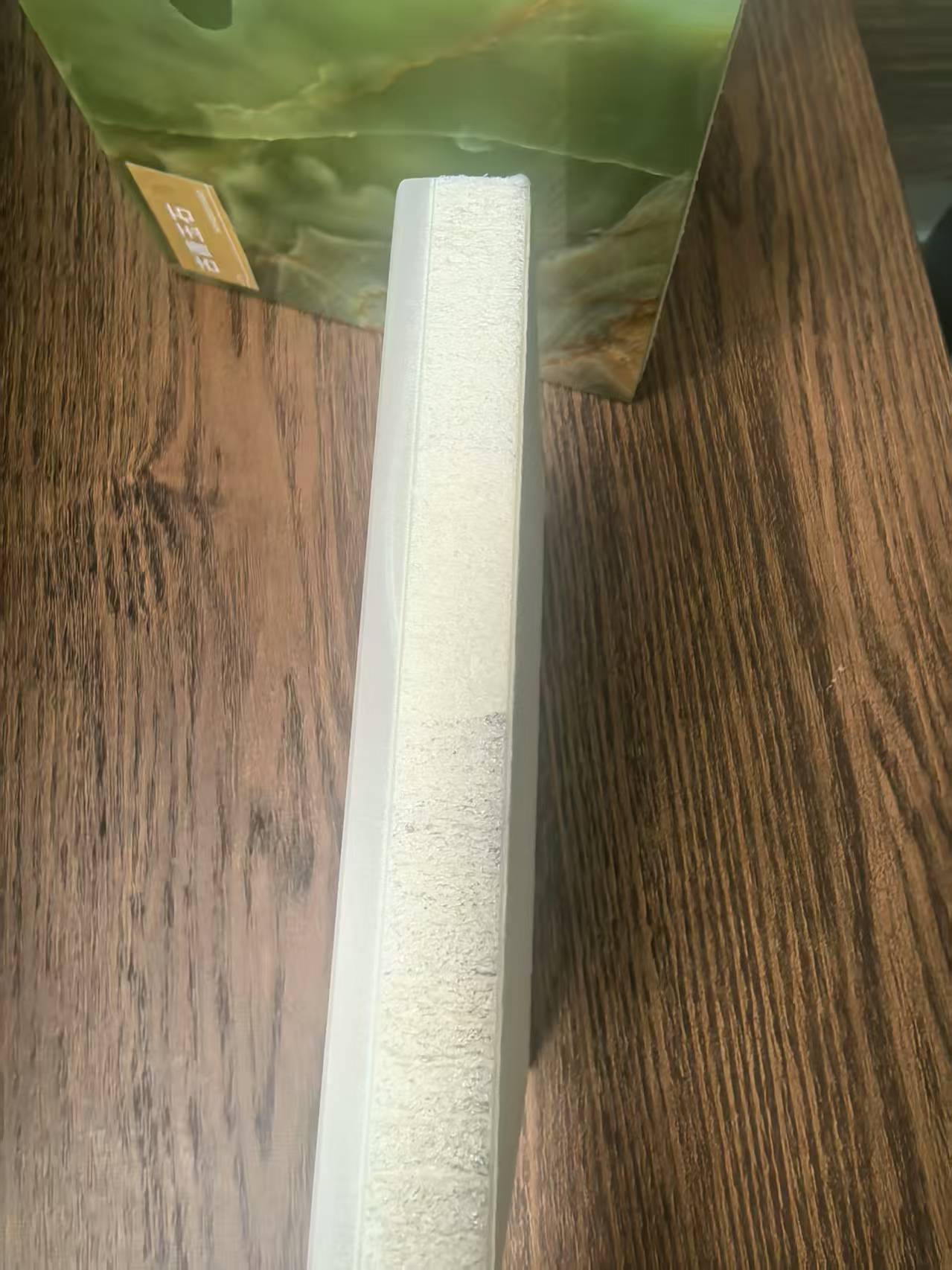

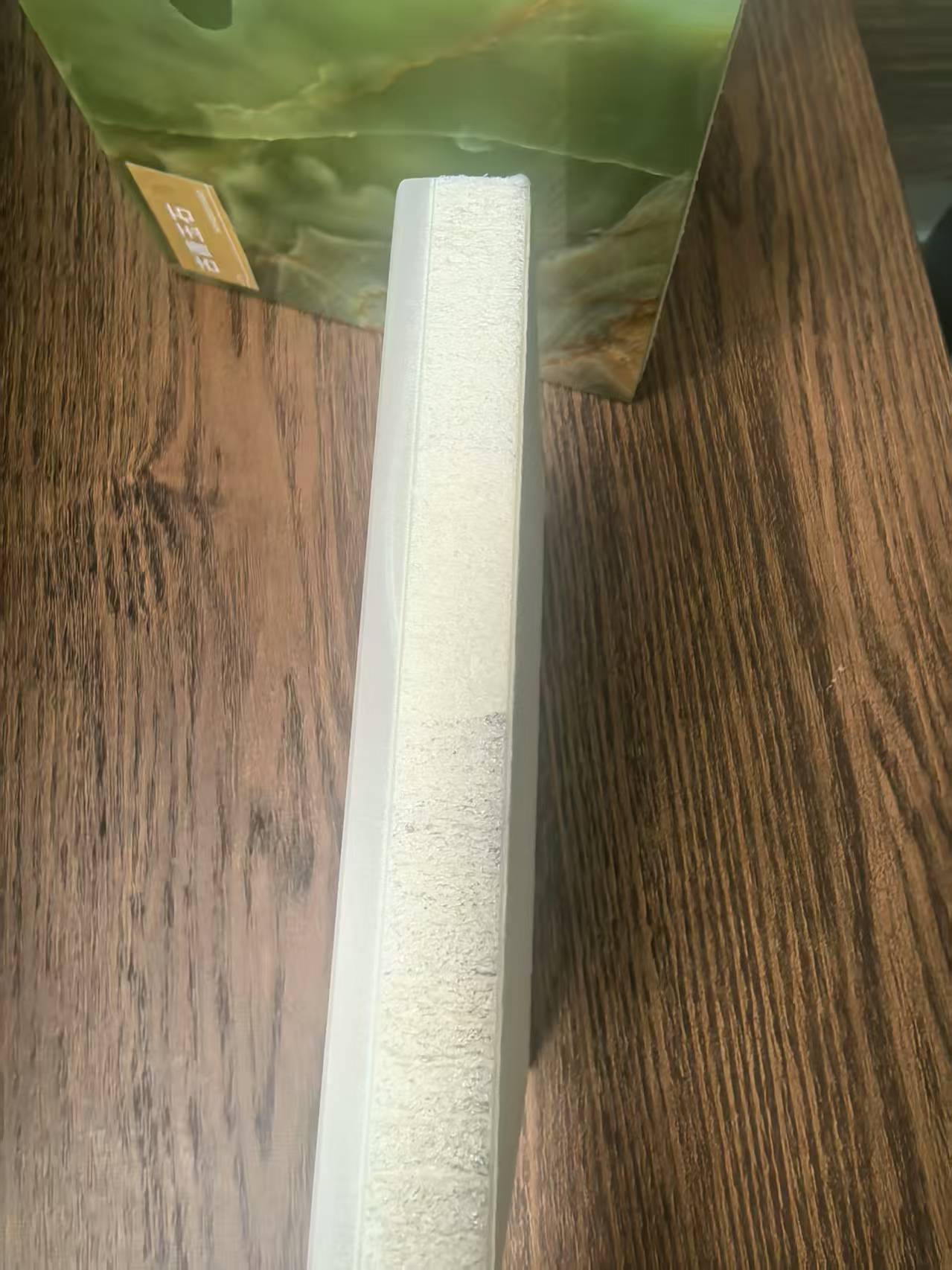

Solving the pain points of wooden boards, with a core in the board, it's more reassuring.Provide lightweight, durable and environmentally friendly boards. One-stop solution from materials to finished products

Get in touch

Featured collection

-

Sold out

Sold outECO marble cart

Regular price $1,899.00 USDRegular priceUnit price / per$2,599.00 USDSale price $1,899.00 USDSold out -

Sold out

Sold outECO Marble Coffee Side Table

Regular price $99.00 USDRegular priceUnit price / per$129.00 USDSale price $99.00 USDSold out -

Sold out

Sold outECO Marble dining table

Regular price $8,499.00 USDRegular priceUnit price / per$10,899.00 USDSale price $8,499.00 USDSold out -

Sold out

Sold outECO Marble flowerpot

Regular price $598.00 USDRegular priceUnit price / per$888.00 USDSale price $598.00 USDSold out -

Sold out

Sold outECO Marble Lightweight Coffee Table

Regular price $1,899.00 USDRegular priceUnit price / per$2,699.00 USDSale price $1,899.00 USDSold out -

ECO Marble Modern Coffee Table with Hemispherical Base

Regular price $1,488.00 USDRegular priceUnit price / per$1,799.00 USDSale price $1,488.00 USDSold out -

Sold out

Sold outECO Marble Round Coffee Table

Regular price $1,255.00 USDRegular priceUnit price / per$1,599.00 USDSale price $1,255.00 USDSold out -

Sold out

Sold outECO Mineral Aluminum Honeycomb Board

Regular price $0.00 USDRegular priceUnit price / per -

ECO Natural Marble Composite Panels

Regular price $0.00 USDRegular priceUnit price / per -

Sold out

Sold outECO PerlaCrystal Panel

Regular price $0.00 USDRegular priceUnit price / per

one-stop partner in lightweight innovation

-

Eco-Furniture & Composite Panels

Lightweight Eco-Furniture & Composite Panels: Kind to Earth, Easy on You Want...

-

ECO Natural Marble & Composite

Natural Marble Home & Composite Panels: Luxury, Lightened Crave the elegance of...

-

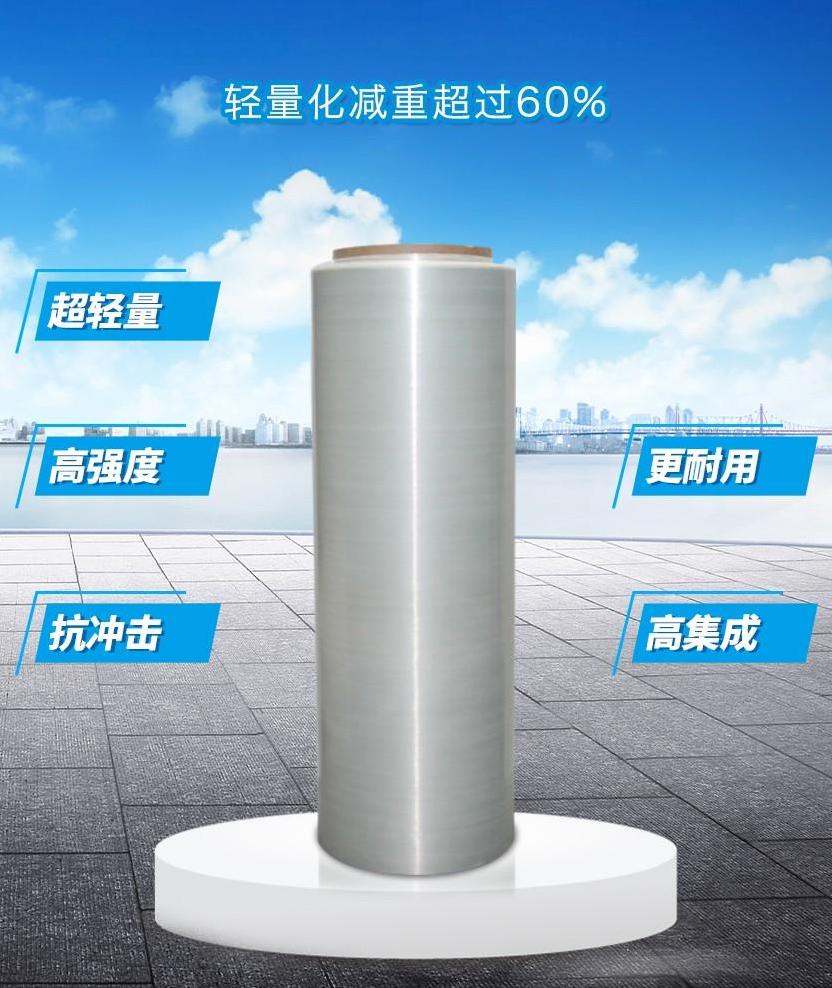

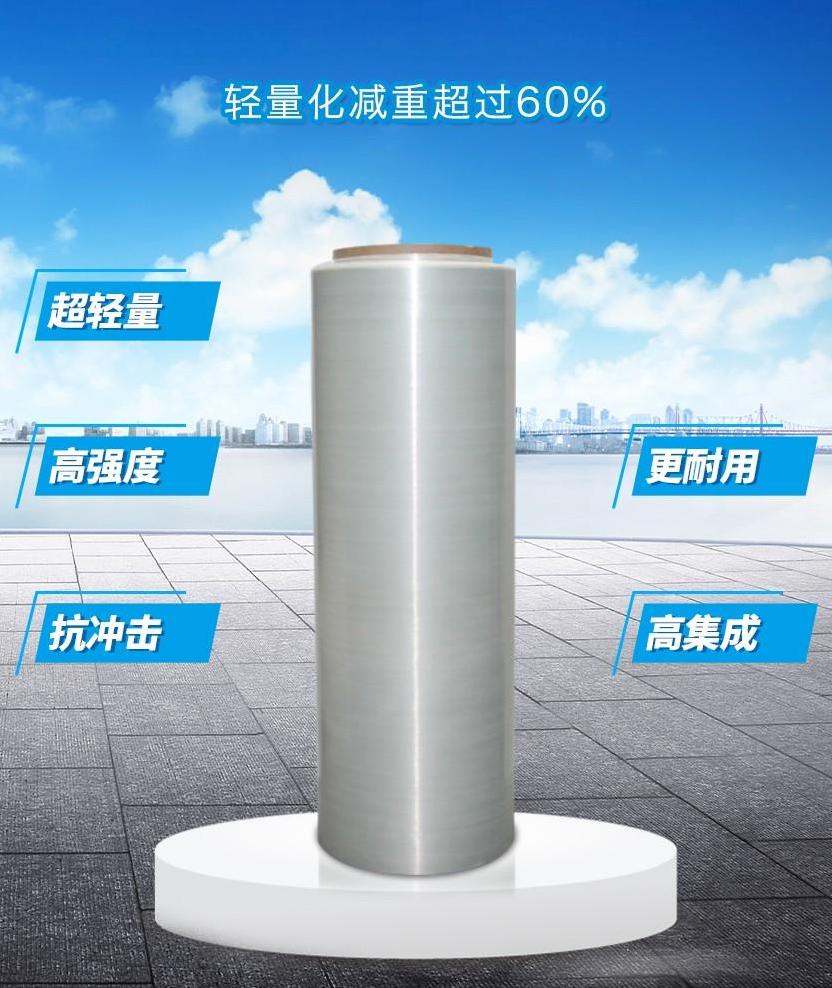

ECO UD Tapes

Thermoplastic Prepreg Unidirectional Tape Strength meets lightness. High tensile strength, low weight,...

ABOUT US

-

AS DESIGNERS

We sculpt surfaces that whisper to light, but engineer cores that shout against compromise.

From oil to green, for the sake of our earth.For the same target cohesion: green innovation.While others polish surfaces, we engineer souls. -

AS MANUFACTURERS

In our zeros lies your freedom:0.01mm tolerancefor perfectionists,0% void coresfor sterile criticality,0 excusesfor unsustainable choices.

-

AS ENGINEERS

We weaponize waste into wonder:

✦ 12 bottles → 1㎡ of carbon-negative armor

✦ 70% weight saved → 40% lower freight bills.

Our commitment to sustainable development and innovation drives us to create unique and high-quality products that enhance your life. From the laboratory to the global market: Our years of innovation in polymer materials have adhered to the original intention of "solving industry pain points".

Honeycomb board composite production line

The latest generation of metal core composite plate continuous production line developed by our company can be switched to produce various types of metal core composite plate.The principle is that through the special composite equipment developed by our company, the metal coil and metal core can be quickly combined at high temperature through the polymer film of special material, and the bonding strength is higher than that of traditional glue and the durability is better

Sandwich composite board production line

Core Superpowers

✅30m/minthroughput:Your deadlines bow to us.

✅0.01mm tolerance: Perfection for surgical rooms & superyacht interiors.

✅Closed-loop alchemy: 12 bottles → 1㎡ carbon-negative armor in 17 minutes flat.

Thermoform Composite Line

Meet the future of composite manufacturing—our fully automated thermoform production line, built for high-volume, multi-material precision.

Why it stands out:

✅ 24/7 Automated Excellence: No manual errors, no delays.

✅ 1-Material, 5-Products Flexibility: Switch between thermoplastic prepreg tapes, CFRT sheets, honeycomb panels, and sandwich boards inunder 30 minutes—no retooling, no waste.

✅ Eco-Certified by Design: Powered by renewable energy, our line uses 40% less energy than traditional methods